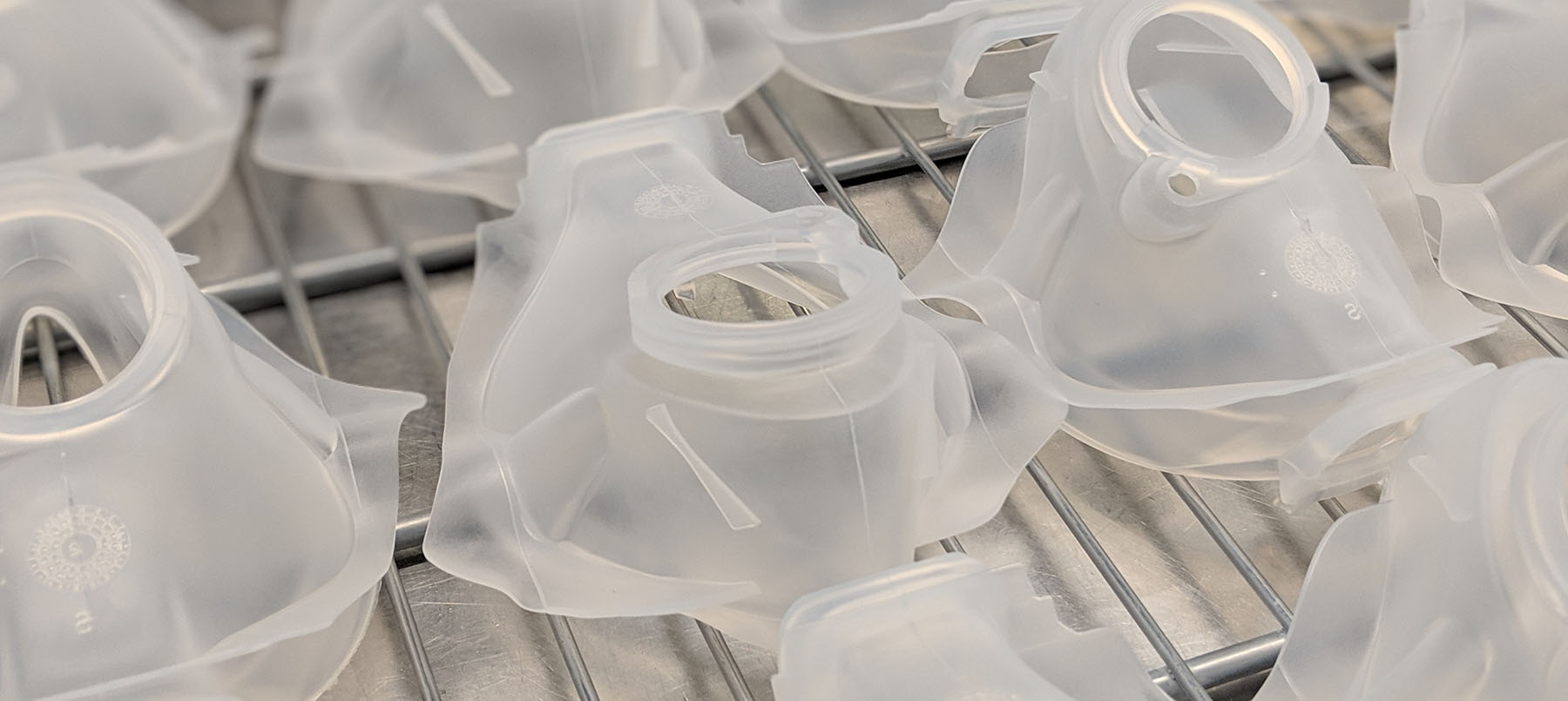

PLASTIC-RUBBER COMPOSITE

Startseite » Products » Plastic-rubber composite

Advantages of plastic-rubber composite parts

From a technological point of view, the 2K process and multi-component injection moulding are proven and established processes for plastic injection moulding.

Whether the components are hard/soft (thermoplastic/TPE composite) or multicoloured, is irrelevant.

For hard/soft components with high mechanical, chemical and/or thermal requirements, thermoplastic elastomers have their limits. The use of rubber-based elastomers (generally known as rubber) is required here. Plastic and rubber composite parts (thermoplastic/elastomer composite) find their applications here.

Up to now, these components have generally been manufactured at different locations in two manufacturing processes. The aim is to manufacture K+K components from one tool at one location in all cases where technical feasibility is combined with cost reductions, thereby creating significant customer benefits.

Advantages

- Weight reduction (plastic instead of metal)

- Corrosion-free (plastic instead of metal)

- Cost-effective injection moulding production

- No adhesive system required

Economic efficiency

- The manufacturing process can be largely automated by dispensing with the use of adhesion promoters.

- No need for multiple handling of parts

- Possible sources of error are avoided and the reject rate decreases.

- Depending on application-specific conditions, cost savings of up to 30% can be achieved.

Fields of application

Wherever rubber parts have to be permanently fastened or fixed. Such composite parts can be found in a wide variety of applications, e.g. damping bearings in the chassis area of motor vehicles, stop buffers, reinforced seals in machines and engines.