NOT ONLY DO WE DEVELOP SOLUTIONS FOR OUR CUSTOMERS, BUT WE ARE ALSO CONSTANTLY ON THE LOOKOUT FOR INNOVATIVE SOLUTIONS.

OUR RANGE OF SERVICES

AREAS OF APPLICATION

Control technology deals with the

automated controlling of dynamic systems.

For many years, we have been supplying customers from this sector with a wide range of sealing products and membranes that require a high level of accuracy and reliability in the final product.

Our sealing gaskets can withstand a broad range of temperature conditions, from minus zero degrees Celsius to high temperatures, with a high level of media resistance. These products are used

everywhere where liquids flow through systems and must be controlled. Our membranes are built-in components of various solenoid and analytical valves and are reliable in keeping the control unit separate from the medias being used.

Years of experience in this field ensures that our customers receive the optimal solution for their needs and requirements.

The automotive industry is one of the most important industries worldwide.

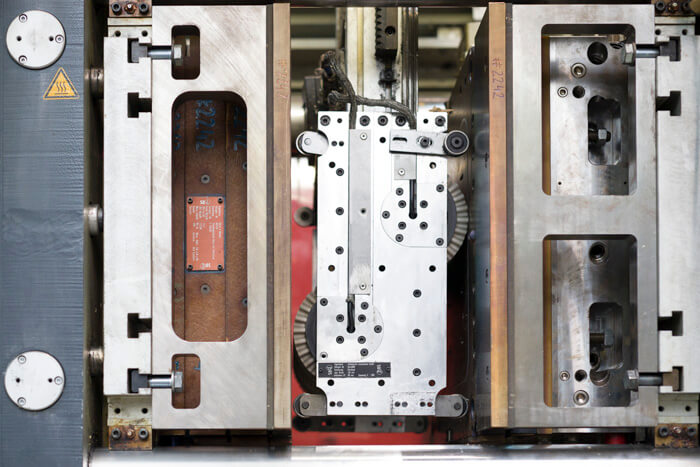

This key industry sector has the highest demands on functionality, quality, scheduling and price in regards to medium and large quantities of serial production. SBG has been meeting these demands for many years and has completed multiple projects for important suppliers to automobile manufacturers. We were successful in these projects by using semi- and fully automatic controlled processes. Together with our customers and our partners in mechanical engineering, parts handling and compounding, these processes were developed according to the requirements of the parts to be produced.

We have set up our own production cell in our production, especially for the automotive industry, in which exclusively medium-sized and large series are produced for our automotive customers and 100% checked for various characteristics for parts requiring documentation and safety-relevant parts with the aid of image processing systems.

The support of this production cell is carried out exclusively by a specially trained team. With this measure, SBG has taken a further step to meet the increasing demands on component quality and the growing number of units. Thanks to optimal project management and a network of strong partners, cost-effective production in Germany for these series can be achieved quickly and reliably.

Take advantage of our experience in the production of elastomer parts and elastomer composite parts “Made in Germany”. Of course we produce at best conditions under the conditions of the IATF 16949!

Suppliers to the household appliance sector have high standards for

rubber moulded parts and rubber composites.

Our parts can be used in appliances with very different uses, such as washing, cleaning, heating, cooling, cooking etc. This requires a very careful choice of the most varied types of elastomer products.

We are able to offer a very large selection of tried and tested rubber compounds that will fulfil the needs of most of our customers‘ requirements. Approval for use with foodstuffs is the main requirement for this sector, and we have developed and accumulated a wide range of suitable compounds that will certainly meet all demands.

SBG is constantly working on new innovations and solutions to ensure the highest possible safety standards at hazardous workplaces.

Our company produces for the market leaders in the field of occupational safety and respiratory protection technology at home and abroad. Years of experience with rubber materials are incorporated into the production of new, more durable rubber compounds to maintain health and personal safety.

High quality standards and constant monitoring of the various production processes are a matter of course for us, especially in this area.

SBG supplies many other different industries in which elastomers and plastic-rubber compounds

can find their application

For example, rubber linings are used in the optical industry when it comes to defined surfaces and their properties.

We also supply our customers for the sanitary sector, in medical technology, the pharmaceutical industry, the aviation industry or in the construction industry and have years of experience as well as the necessary standards. We would be pleased to receive an enquiry for your individual moulded part and develop a suitable solution for you together with our technology.